Melhor Preço Gupsum Board perfil De Metal rolo dá forma à máquina

Informação básica

Modelo: ZT-002

Descrição do produto

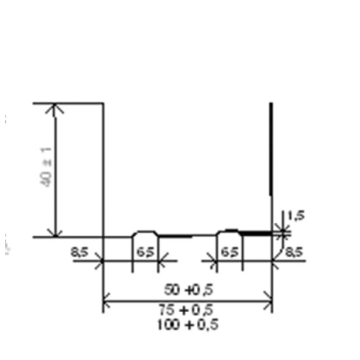

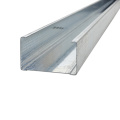

Nós temos a experiência rica em fazer Gupsum Board perfil de Metal máquina de prensagem. Esta máquina pode oferecer aos construtores uma alternativa competitiva às tradicionais treliças de madeira. E a seguinte máquina, nós somos especialmente design para o Uzbequistão. Aqui estão alguns perfis de desenho para sua referência. E eles também podem ser usados como teto e drywall. E é popular em todo o mundo.

A nossa máquina suporta espessuras de material de 0,4-1,0mm de aço leve com a especificação técnica completa de engenharia. Projetado e pré-projetado por experientes especialistas em treliça usando apenas o mais recente software. Normalmente nossa máquina pode fazer treliça para a Índia, Austrália, Egypet e outros países. As formas das treliças são como forma de chapéu furring, forma de U, forma de C, forma de L e outros. E há mais perfil de desenho proprfile de metal para sua referência:

|

Un-coiler System

|

Usage: It is used to support the steel coil and uncoil it in a turntable way. Passive uncoil pulled by roll forming system Loading capacity: 3T Uncoiling width: 127-205 mm Inner diameter: 450-550mm |

|

Entry Beach

|

Usage: Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron. |

|

Main Roll Forming System

|

Feature: Ensure stability, precision and lifetime. Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, gear transmission (the first and the last roller, the down roller should be attached with the upper one with the gear drive.), roller surfaces polishing, hard plating, heat treatment and galvanization treatment. The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Length of the main part: about 3000-800-1400 Weight of main part: 3 tons Voltage : 380V/50HZ3Phase (as customer`s request) Roller fixer : Guide column Frame : middle plate welded Memorial arch frame type Frame thickness:25mm Drive mode: gear Material of rollers: GCr12MoV Material of shafts: 45# steel with tempering Diameter of shafts: φ40mm Number of rollers : 10 rollers Main power: 3kw Cycloidal planetary gear speed reducer)

|

|

Shearing Mechanism

|

Feature : Ensure stability, precision and cutting speed Function : Automatic cutting controlled by PLC It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades: Gcr12MoV quenched Power supply : hydraulic power Frame : Pillar style with rack & pinion system Stroke switch : non-contact photoelectric switch Components: It contains one set of cutting tools, one hydraulic tank and one cutter machine.

|

|

Hydraulic Station

|

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job. Hydraulic motor Power: 3kw

Hydraulic oil: 46# Volume: L Components: The system includes a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And two sets of electromagnetism valves.

|

|

Electric Control System

|

Feature: 1.Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime. 2.Other electric element are Delta 3.Equipped with movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and safety. |

|

Counter |

One counter gauges length, pulses, and decides length. Omron encoder for length measurement. |

|

Products receiving tables |

It adopts welded steel and supported roller to transmit the products. |

|

Accessories |

1.Easy damaged parts: conk 2 pcs, fuse-link 4 pcs 2. Rubber mat 1 pcs; 3.Bolt spanner 1 pcs |

Nosso serviço:

Método de pagamento: 30% T / T adiantado e saldo de 70% após a confirmação da inspeção .

Garantia 1. Um ano, e vamos fornecer o suporte técnico para toda a vida. 2. Precisa de um técnico 3. Tempo de treinamento: uma semana (contém o tempo de instalação e ajuste)

Grupo de Produto : C/U/canal & T barra Roll Forming Machine > Perfil de drywall Perfiladeira